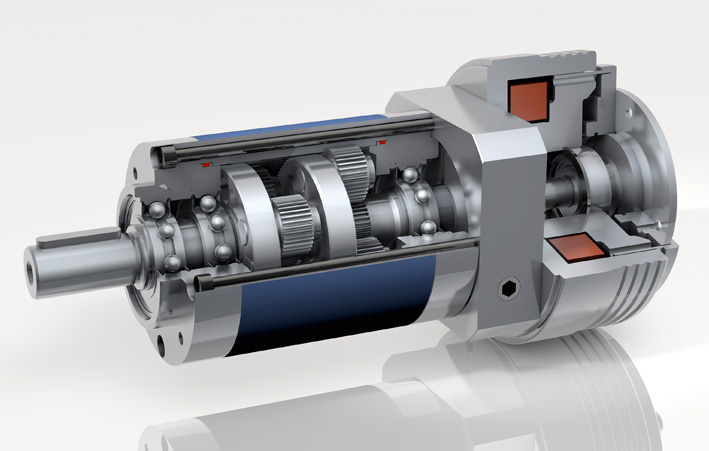

Hysteresis brake with Gearbox

Depending on requirements and application, our hysteresis brakes can be combined with a 1- or 2-stage planetary gearbox using a flange kit. The combination can achieve torques from 9.9 Nm up to 180 Nm (taking into account the maximum slip power). Our planetary gearboxes (PLGS series) are produced in Germany, which guarantees a high standard of quality and reliability.

The hysteresis brakes developed and manufactured by a&g in combination with a gearbox are

characterized by high precision and repeat accuracy as well as the freedom from wear that is

characteristic of this mode of operation. As a result, tensile forces or torques can be infinitely

adjusted. In addition, a&g offers a cost-effective and universal control electronics (RHE).

The hysteresis brakes developed and manufactured by a&g in combination with a gearbox are

Due to their repeat accuracy and freedom from wear, our hysteresis gearbox combinations are widely used in the field of test bench technology or for winding machines with unwinding processes with high torques.

Functional principle

The most important components of hysteresis brakes and clutches are their rotor and pole structure. This pole structure is composed of an external body and an excitation coil. These pieces constitute the static or the actuated part of the brakes and clutches. The result is a braking and coupling force caused by magnetic interaction. Moreover, the pole structure consists of an internal and external pole structure, which is separated by an air gap.

The rotor constitutes the major difference between hysteresis brakes and clutches: Regarding hysteresis brakes it is the moving part, whereas it is the output for hysteresis clutches.

Typical applications

Hysteresis technology is usually employed for winding processes of yarn, textile, cable, fabrics, paper, plastic layers, etc. Thus the brakes and clutches of a&g are used in mainly all high technology applications of winding and stranding industry.

As a result of their high repeatability, their wear- and maintenance free feature, these devices are also used in test bench technology.